Senior Engineering Report: December

December 29, 2018

December may be a short month for school, but that doesn’t stop students from taking full advantage of it! On the contrary, our seniors in the Engineering Academy accomplished quite a lot before the break.

We started the month strong with a field trip to the local carpenter’s union. Once we arrived, a senior instructor talked to us about the process of becoming an apprentice carpenter. There’s plenty of existing talk about college as a post high school option, so it was nice to hear about vocational education for a change. He then gave us a tour around the building. We saw a floor of carpenters, noisily working in action. There was also some cool devices to look at, such as a vacuum table to hold down materials and a helmet for welding simulation. My dad is a part of the carpenter’s union himself, so I was personally interested in seeing something that was close to his field of work.

The majority of class time this month was spent working with new tech: FlowArm. This neat little device is a robotic arm with several points of articulation, including base rotation, a twisting wrist, and a moving claw. Its primary function is to operate like a crane, picking up objects in one spot and moving them to another. The arm is controlled by a computer application, where the position of each moving part can be adjusted. Users can even record specific sequences of movement to create a repeatable function; one assignment tasked students with using this technique to program a stacking operation.

https://www.youtube.com/watch?v=gbE71cucDPo

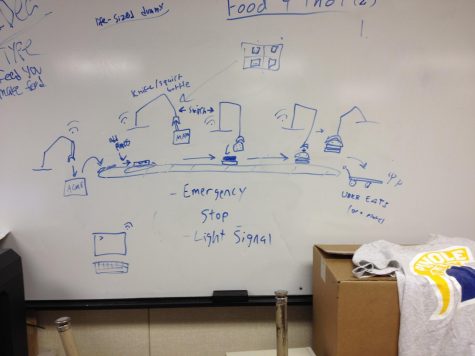

FlowArm will play a big part in the semester final for the Computer Integrated Manufacturing class. Instead of a normal exam, the final will see students grouping up to create a fully automated model of a manufacturing process. Personally, I have the pleasure of working on a super-project with 7 other students! We’ve only begun the brainstorming phase so far, but it’s already been a blast. Our initial idea? A factory line for mass-assembling sandwiches. (The edibility of the finished products is to be determined.)

In other news this month, I had the extremely fortunate opportunity to visit the inside of our new school campus! Our teacher, Ms. Johnson, was inspecting the future engineering classroom, and I (alongside fellow students Deven Irwin and Chris Gauthier) was lucky enough to tag along. We all donned hard hats and orange vests, and after crossing a makeshift plank bridge, we were in the building. I was immediately blown away by the scale of the building: looking up at the third floor was dizzying. We were surrounded on all sides by the construction process, which reminded me a lot of the carpentry field trip.

The awe didn’t stop once we reached the classrooms. Although it was devoid of furniture, the engineering computer room still dwarfed the size of our current portables. It even includes a separate classroom that practically doubles its size. Other rooms were much more modest, but they still impressed nonetheless. For example, we got to see a chalkboard that slides back to reveal storage space; I’m certain our teachers will greatly appreciate this feature.

As we were leaving the construction site, Deven noted that the hallways felt a bit cramped. In retrospect, the cause is likely the idea of hallways in the first place. After all, students on the portable campus are used to roaming free, open space when navigating from class to class. Adjustment might be necessary during the initial transfer between campuses, but the new school should offer plenty of advantages that more than make up for it.

That concludes this month’s senior engineering report. On behalf of the Spartan Ink crew, we hope that your break is going well, and we’ll be back in full force once class resumes!

(Special thanks to Ms. Johnson and Lathrop Construction for having us on the new classroom inspection!)